Project: Waterschap Hollandse Delta

Saving Electricity and Increasing Reliability at Waterschap Hollandse Delta

Initial situation: waste, wear, and maintenance pressure

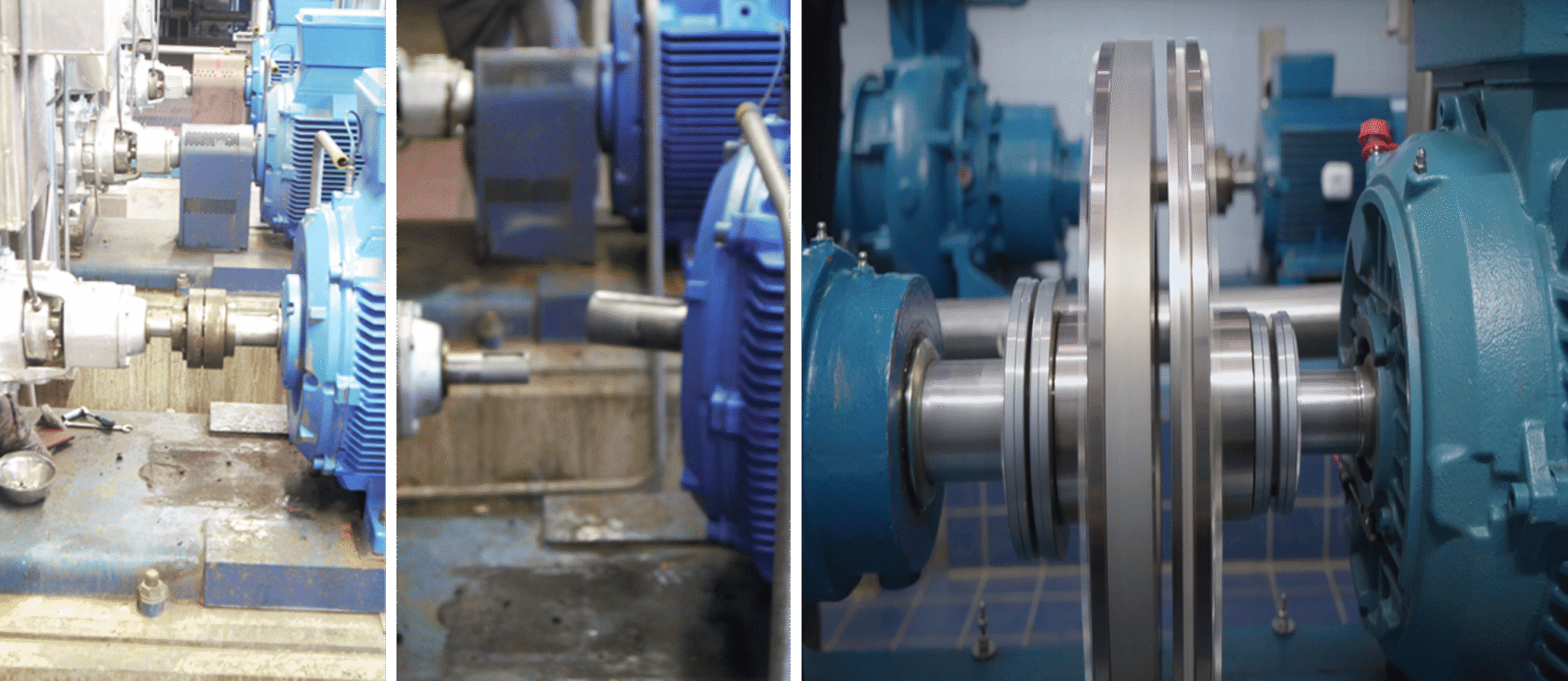

At a pumping station of Waterschap Hollandse Delta in Oud-Beijerland, a familiar issue occurred. The pump installation had, as is common practice, been oversized during design. However, this led to structural electricity waste, cavitation, excessive vibrations, and additional wear on various components such as the pump, piping, and check valve. There was also a relatively high maintenance burden, while technical personnel are becoming increasingly scarce.

Objective: more efficient, more reliable, and future-proof

Waterschap Hollandse Delta wanted to optimize this installation without major modifications. There was also no technical or economic room for an electronic control system for the electric motor. The goals were clear: reduce overcapacity, decrease mechanical stress, and achieve electricity savings with a system that is easy to implement and delivers immediately measurable results.

The solution: retrofit with the Zytec Non-Contact Drive

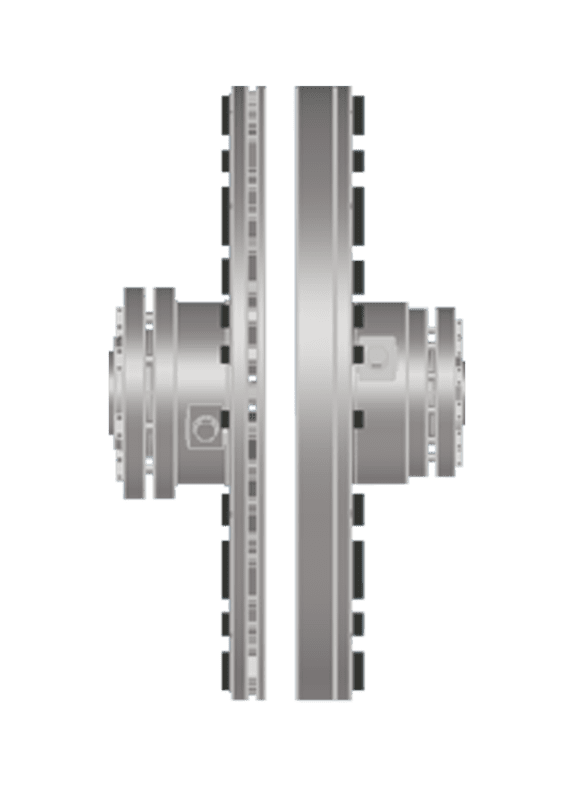

The choice was made for the Zytec Non-Contact Drive, a contactless drive that could be installed within 3 to 4 hours. This made it possible to easily set the pump to its Best Efficiency Point (BEP). Thanks to the absence of physical contact between motor and pump, wear and maintenance are minimal, and vibrations are effectively dampened.

The result: lower costs, higher reliability

The optimization delivered immediate, tangible benefits:

- Overcapacity was reduced from 320 m³/h to 220 m³/h

- Electricity and cost savings by avoiding overproduction

- Strong reduction in vibrations and cavitation

- Less wear on the check valve thanks to shock absorption

- Less maintenance and increased operational reliability

Ready for the future

This application demonstrates how quick and effective sustainable optimizations can be. The Zytec Non-Contact Drive is suitable for existing pumps and fans from 7.5 to 375 kW and can save up to 30–50% electricity. This makes it a powerful solution for companies and organizations aiming to make their installations future-proof, energy-efficient, and low-maintenance.

Want to see how this works in practice?

Watch it in the video below: Testimonial from Waterschap Hollandse Delta.

"*" indicates required fields