Project: Tata Steel

Tata Steel’s pumps are now completely maintenance free (and save up to 50% energy every day).

Project: Tata Steel

One of the best-known industrial companies in the Netherlands is Tata Steel. How can a ‘small’ detail such as a non-contact drive ensure completely maintenance-free pumps for years on end? And how is it that this results in daily energy savings of up to 50%?

Zoom in on the installation: Cold Rolling Mill 22

At Tata Steel’s Cold Rolling Mill No. 22, steel coils are rolled to a reduced thickness on four rolls. This process releases an enormous amount of heat, which is cooled by a special rolling fluid. The fluid is critical to the process and is pumped around the plant throughout its operating hours. In the basement of Cold Rolling Mill 22, eight pump sets (transfer pumps) take care of this process.

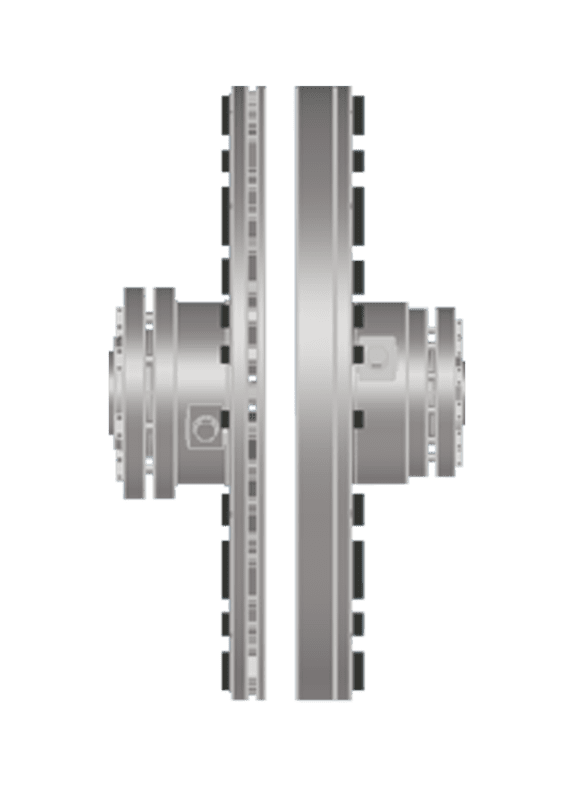

In 2016, Tata Steel decided to replace the drives in the pumps with Zytec’s non-contact drives. Since then (we are writing this article in 2023) the pumps have been running completely maintenance free.

Why is this single detail so critical to a maintenance-free process?

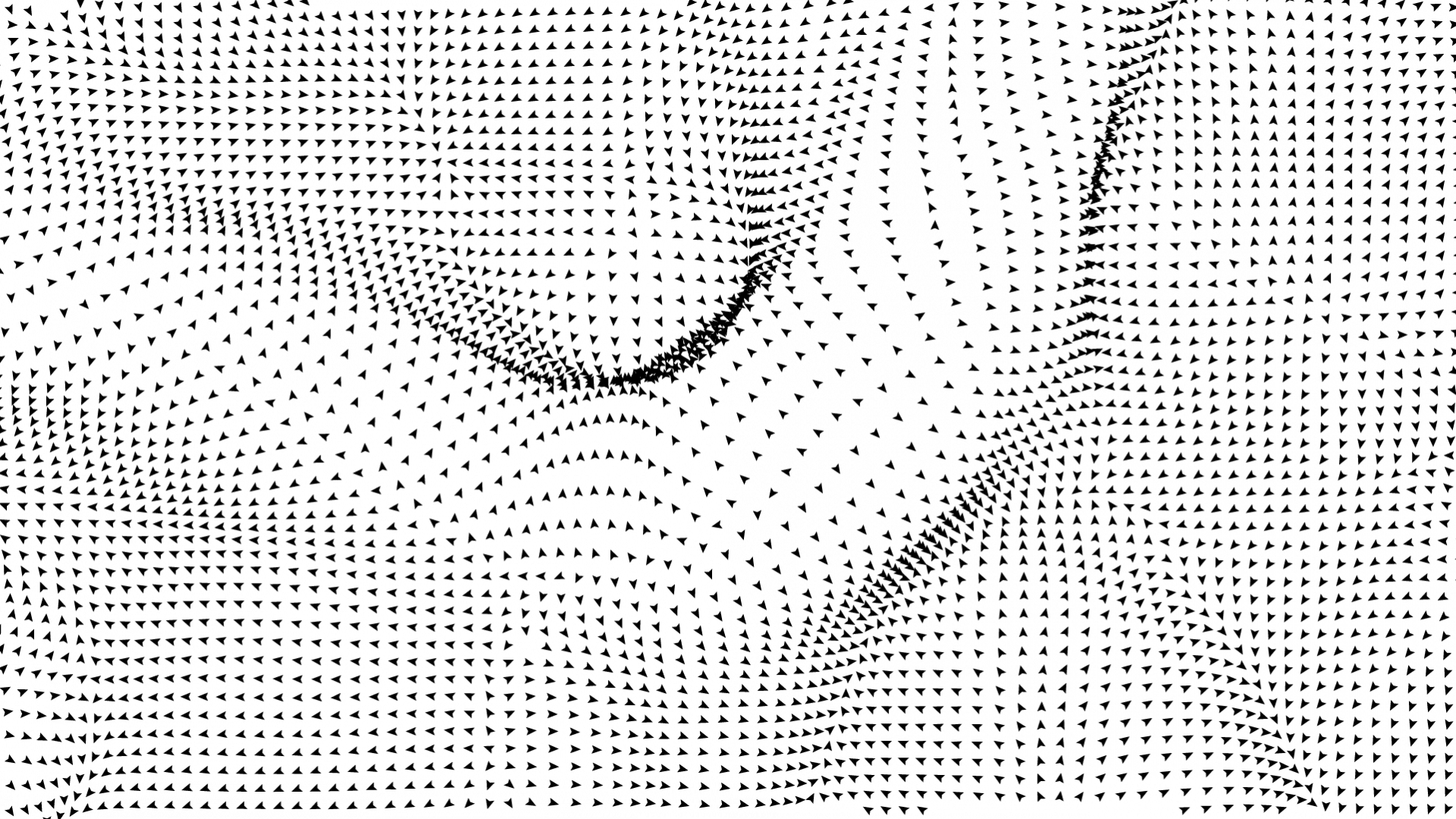

Typically, pumps are oversized. This means that much more capacity is included in the design than is actually required during operation. In operation, this was solved for the Cold Rolling Mill pumps by fitting a choke valve to the piping. This allowed the volume to be regulated, but the excess capacity still consumed much more energy than was needed for the operation. In addition, the use of choke valves resulted in a highly turbulent flow and a lot of cavitation at the valves, pipes and inside the pump.

There was a lot of damage to the pumps due to leaking seals and broken bearings. In short, pump maintenance was intensive and took a lot of time and manpower. Also, on a regular basis, it was necessary to stop production to repair, for example, leaking pipes – with all the associated costs of production downtime.

The solution: non-contact drives, with a special “side effect”

Long before 2016, Tata Steel had been looking for another speed reduction solution. Variable Frequency Drives (VFD)could provide a solution in theory, but proved far too complex and expensive in operation.

After a long search, Tata Steel came across Zytec’s non-contact drives. Not only do they provide a lower speed on the load side, so there is no excess capacity, but they also have other surprising “side effects”.

In two days, the couplings on four of the eight pumps were replaced with non-contact drives. This can be done very easily and without stopping production. In fact, four of the eight pumps are on standby anyway. This allowed the plant to continue operating with four pumps while the couplings in the other pumps were replaced.

The result: maintenance-free and energy savings of 1 million kWh per year

Because the non-contact drives provide optimum flow, the choke valves can be opened all the way. Leaks and seal or bearing problems are history. The continuous flow has eliminated breakdowns, damage and maintenance. As a result, there has been no need to change to the redundant pumps since 2016.

After installing the non-contact drives in the pumps, a performance measurement was carried out immediately. The pumps have a capacity of 75 kW and by installing the non-contact drives, a reduction of 50 % in the pump’s electricity consumption was achieved. In other words, a saving of one million kW on an annual basis, comparable to the annual energy consumption of 340 households.

In addition, there have been no production loss since 2016. Add to this the savings in maintenance and breakdowns, in material and man-hours, and you can see how a huge cost reduction has been achieved in only two days’ work.

Want to see how it works in action? The Tata Steel people are happy to show you their amazing installation in this video:

➔ Companies and institutions with an energy consumption of 50,000 kWh of electricity or 25,000 m3 are subject to the new Dutch Energy Saving Obligation. If your company is subject to this requirement, you may be on a complex and time-consuming path. But by looking at the details, rather than the big picture of energy savings opportunities, you may be able to move forward sooner, faster, and cheaper than you think.

Curious what to expect? Download our white paper.

↓

Whitepaper

Download

"*" indicates required fields