Pick your product

At Zytec, we specialize in revolutionary magnetic coupling technology that transforms the way rotating equipment operates. Our non-contact drives provide numerous benefits, ensuring enhanced performance, efficiency, and reliability across various industries.

What is a Zytec Non-Contact Drive?

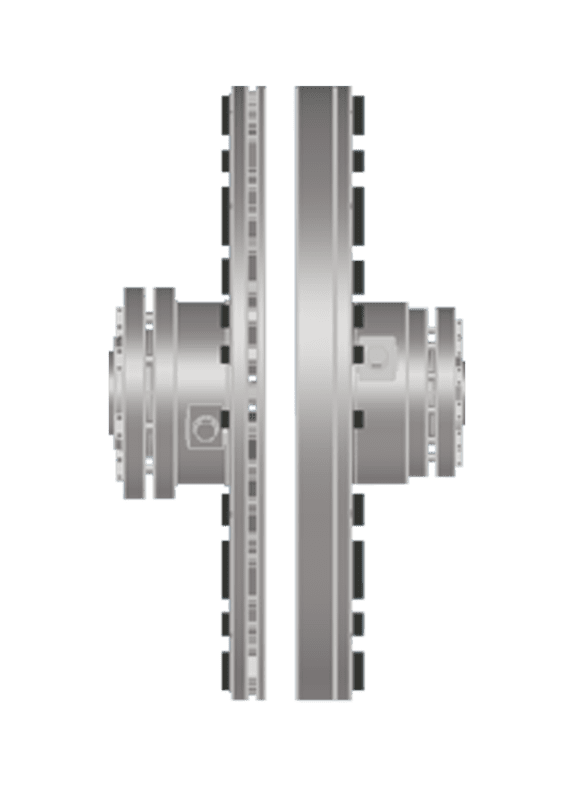

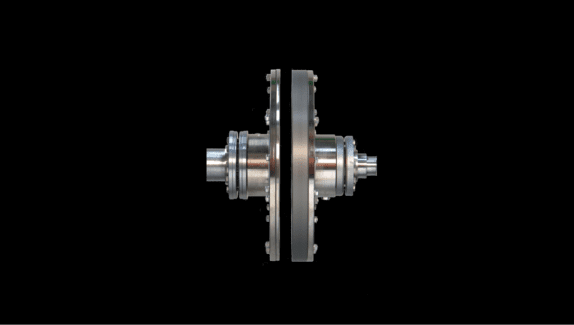

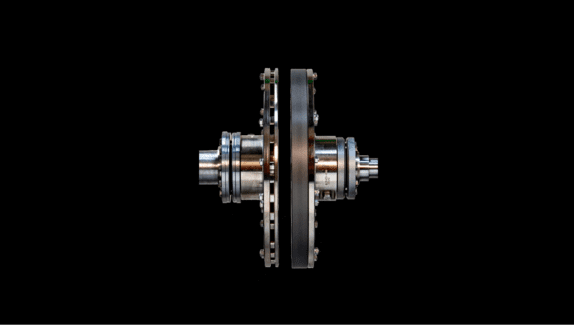

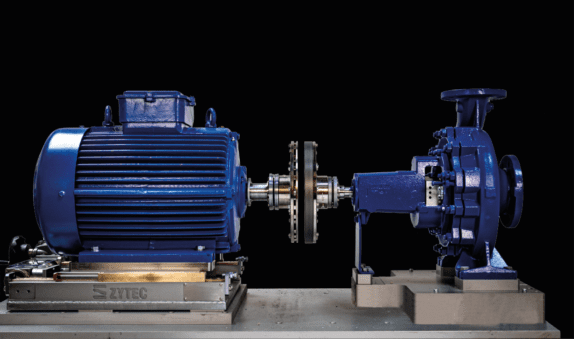

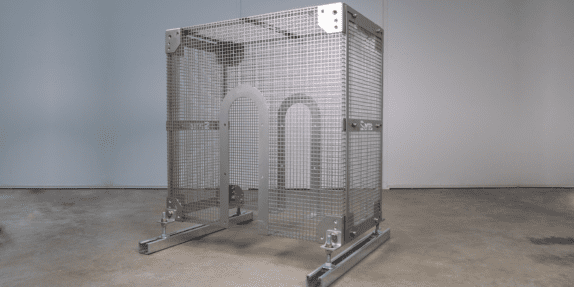

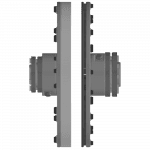

Zytec’s non-contact drives are advanced devices that enable contactless power transmission between the motor and the driven equipment. Unlike traditional mechanical couplings, our non-contact drives utilize powerful magnets to transfer torque and eliminate the need for physical contact. This innovative technology offers a wide range of advantages for industrial applications.

How Does Zytec Non-Contact Drives Work?

Zytec’s non-contact drives consist of two parts: the driver and the driven unit. The driver unit is connected to the motor, while the driven unit is linked to the equipment that needs to be powered. The magnetic field generated by the driver unit efficiently transfers torque to the driven unit without any physical connection. This contactless power transmission ensures smooth operation, minimal maintenance, and improved system performance.

Advantages of Zytec’s Non-Contact Drives:

Maintenance-Free Operation: With no physical contact or wear, Zytec non-contact drives eliminate the need for lubrication and regular maintenance, resulting in significant cost savings.

Enhanced Efficiency: The contactless power transmission minimizes energy losses, leading to higher overall efficiency and reduced energy consumption.

Increased System Reliability: By eliminating mechanical wear and potential leakage points, Zytec non-contact drives enhance system reliability and reduce the risk of downtime and costly repairs.

Improved System Safety: The absence of physical coupling parts eliminates the risk of contamination, leaks, and potential hazards, ensuring a safer working environment.

Overcoming Challenges

At Zytec, we understand the concerns associated with adopting new technology. To overcome the disadvantages, we offer:

Comprehensive Support: Our experienced team provides guidance throughout the integration process, ensuring a seamless transition and minimizing any technical challenges.

Cost-Benefit Analysis: We assist you in evaluating the long-term cost savings and return on investment (ROI) to showcase the value of implementing the non-contact drive.

Customer Applications

Zytec non-contact drives have been successfully applied in various industries, including:

- General Industry

- Water and Waste Water

- Heating Ventilation Air-Conditioning (HVAC)

- Chemical Industry

- Oil and Gas Industry

- Maritime Sector

- Pulp and Paper Industry

- Mining

Explore the potential of Zytec non-contact drives for your specific needs and experience the transformative power of contactless power transmission.

Contact us today to discuss your requirements and unlock the full benefits of Zytec technology.

Too good to be true? One detail, significant change

On the large scale of industrial installations, a drive may seem like ‘just a detail’. But by switching to non-contact drives, significant changes occur. For some, it may sound too good to be true. They wonder how such large maintenance and energy savings can be achieved so quickly. We need to explain thoroughly how this is possible, and that is why we are of more than happy to provide you with:

- All the (technical) details

- Amazing business case results and examples from a variety of installations at leading international customers

- Customers who communicate this cutting edge technology as their new best practice

- Dedicated expert partners for local support, engineering and installation

Frequently Asked Questions (FAQ)

Q: What is Zytec’s non-contact drive?

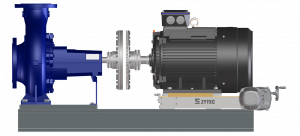

A: Zytec’s non-contact drive is an innovative technology that enables contactless power transmission in rotating equipment such as pumps, fans, generators, compressors, and conveyors. It utilizes magnetic coupling to eliminate the need for physical contact between components, resulting in improved efficiency, reliability, and reduced maintenance.

Q: How does the non-contact drive contribute to energy savings?

A: The non-contact drive achieves energy savings by minimizing frictional losses that occur in traditional contact-based drives. With the elimination of physical contact, energy efficiency is significantly improved, leading to reduced power consumption and lower operating costs.

Q: What are the benefits of using Zytec’s non-contact drive?

A: Some key benefits of Zytec’s non-contact drive include:

- Enhanced energy efficiency and reduced operational costs

- Improved reliability and minimized downtime

- Versatility for various applications and industries

- Future-proof solution that adapts to changing demands

- Reduced maintenance requirements and extended equipment lifespan

Q: Is the non-contact drive suitable for my industry/application?

A: Zytec’s non-contact drive is suitable for a wide range of industries and applications. It finds applications in sectors such as general industry, water and wastewater, HVAC, chemical industry, oil and gas, maritime sector, pulp and paper industry, and mining. It can be applied to rotating equipment used in these sectors, providing optimized performance and efficiency.

Q: How can I integrate Zytec’s non-contact drive into my existing equipment?

A: Integration of Zytec’s non-contact drive into your existing equipment can be done through a professional installation process. Our team of experts will work closely with you to assess your equipment and develop a customized integration plan that ensures seamless implementation and optimal performance.

Q: What kind of support does Zytec offer after installation?

A: Zytec provides comprehensive support after installation. Our dedicated support team is available to address any queries or concerns you may have. We offer technical assistance, maintenance guidance, and prompt response to ensure the continued performance of your equipment.

Q: How do I get in touch with Zytec for more information or to request a quote?

A: To get more information or request a quote, you can reach out to our team by info@zytec.eu. Our representatives will be happy to assist you and provide all the necessary information you need.

Remember, if you have any specific questions or require further assistance, don’t hesitate to contact us. We’re here to help!