Project: Air Liquide Charleroi

High-level cooling

Air Liquide is a global leader in industrial and medical gases. In Charleroi, the company produces various gases for the industrial and healthcare sectors. During this production process, a great deal of heat is generated. To keep the process stable and safe, this heat must be continuously removed. This is done using six large cooling towers, each equipped with fans operating at a height of 15 meters.

These fans are essential for the cooling process. A malfunction in one of the towers can lead to reduced cooling capacity and, consequently, production losses.

The challenge: vibrations, wear, and maintenance

Until 2017, the fans were driven by a traditional drivetrain consisting of an electric motor, gearbox, shaft, and fluid coupling. In practice, this system caused significant vibrations, mainly due to the natural imbalance of the fan blades. These vibrations were transmitted through the shaft to the entire drivetrain, leading to damage and high costs.

Although there were no unsafe situations or oil leaks, the potential risk of such incidents was a major concern. A leak or mechanical failure could result in high repair costs, production downtime, and environmental contamination — something that must be avoided at all costs at a site producing medical gases.

The goal, therefore, was to minimize these risks and increase operational reliability.

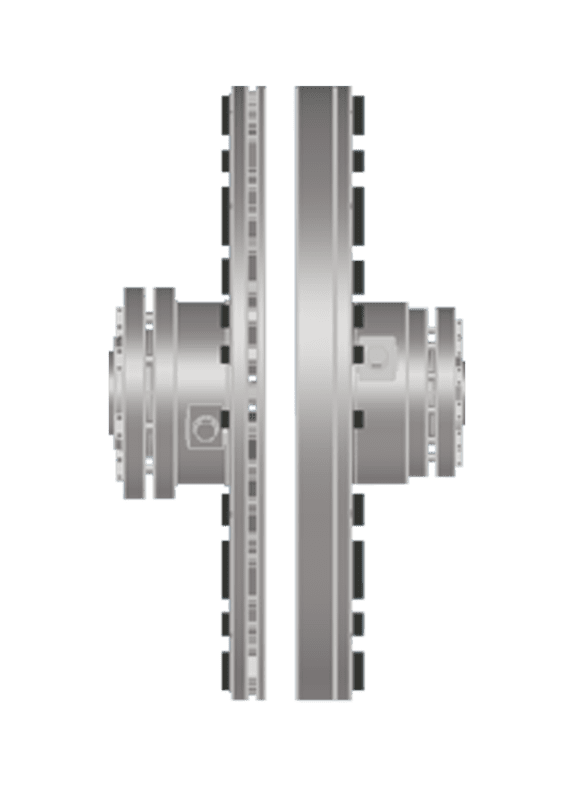

The solution: the Non-Contact Drive by Zytec

Frédéric Steinier, responsible for the technical installations at Air Liquide Charleroi, searched for a reliable and low-maintenance solution. In 2017, the first cooling tower was equipped with a Zytec Non-Contact Drive — a magnetic coupling without mechanical contact between the motor and the fan.

Thanks to the magnetic principle, torque is transmitted entirely without contact. As a result, vibrations are no longer passed on to the drivetrain, allowing the entire system to move freely. Wear and leakage have been eliminated, and the risk of damage has been removed.

The results were so positive that Air Liquide decided to equip all six towers with the Non-Contact Drive. The final installation was completed in 2022.

The result: stable operation without downtime

Since the installation of the Non-Contact Drives, the fans have been running flawlessly and without any maintenance interventions. The greatest benefit lies in the significantly reduced risk of consequential damage. By replacing the fluid couplings, the likelihood of wear, leakage, and downtime has been greatly reduced.

In addition, the amount of work performed at height has decreased, as maintenance personnel now require fewer interventions. The Non-Contact Drives therefore provide a sustainable and reliable solution for a critical installation where dependability and continuity are essential.

Summary – Benefits for Air Liquide

✅ Reliable cooling without downtime since 2017

✅ No mechanical wear

✅ Less maintenance at 15 meters height, improved safety

✅ Lower maintenance costs and higher reliability

Want to see how it works in practice?

Stay tuned for the upcoming video featuring Zytec engineer Aziz and Frédéric Steinier from Air Liquide Charleroi, and discover how the Non-Contact Drive ensures maximum reliability — even at 15 meters height.