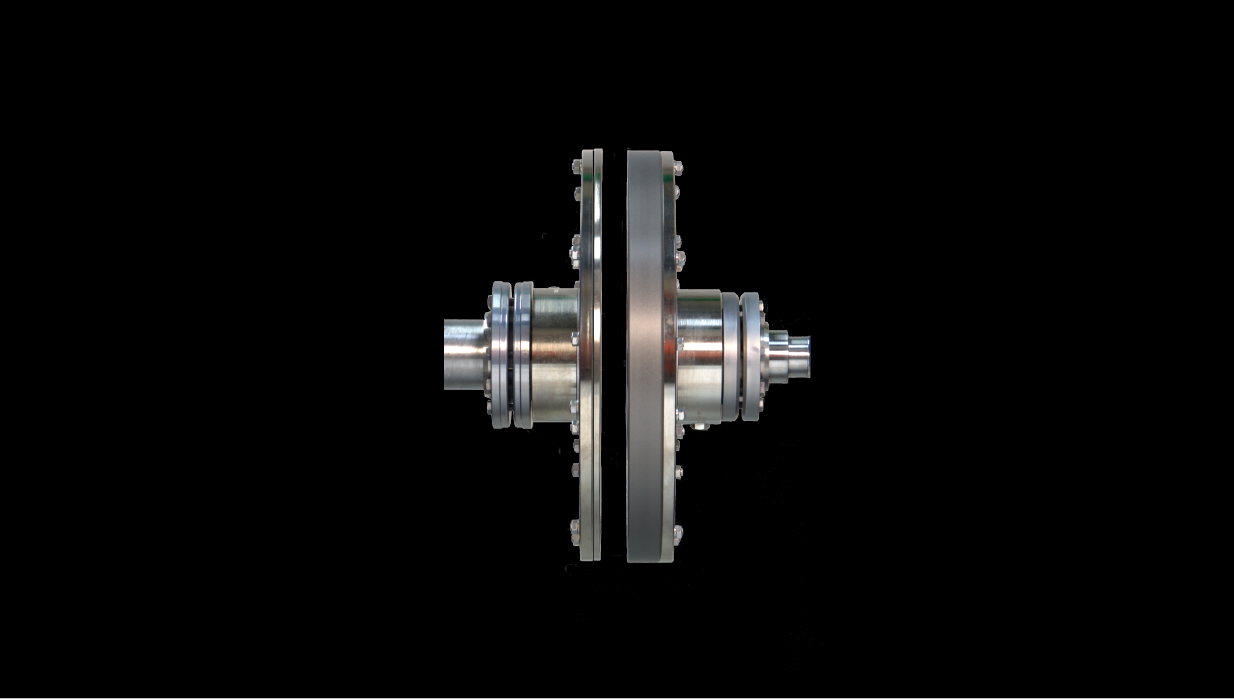

F-TORQ

Fixed Speed Drive

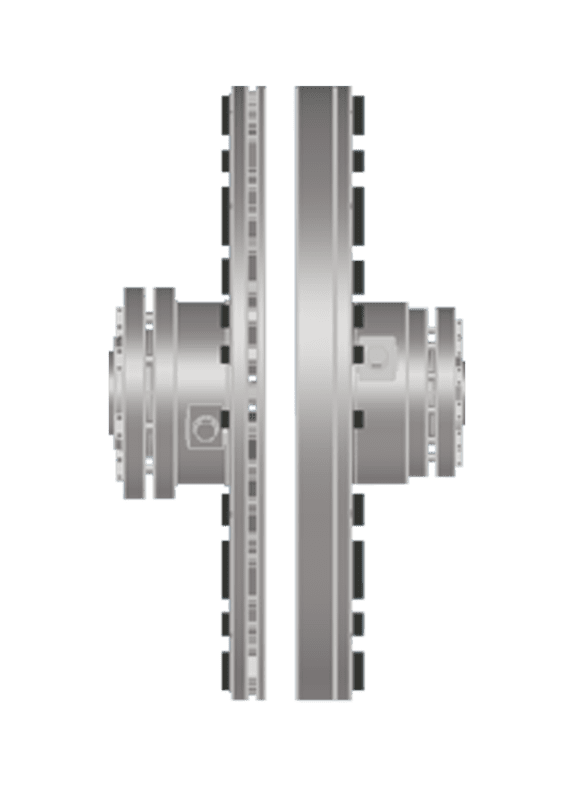

F-TORQ

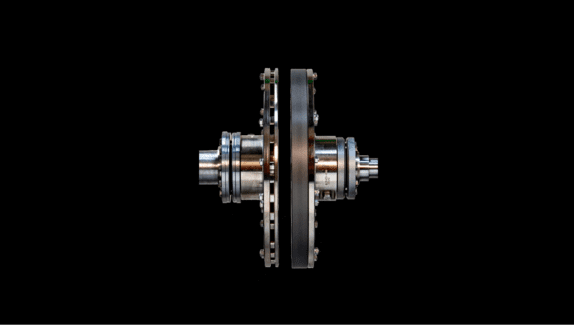

The unique Non-Contact Drive for fixed speed

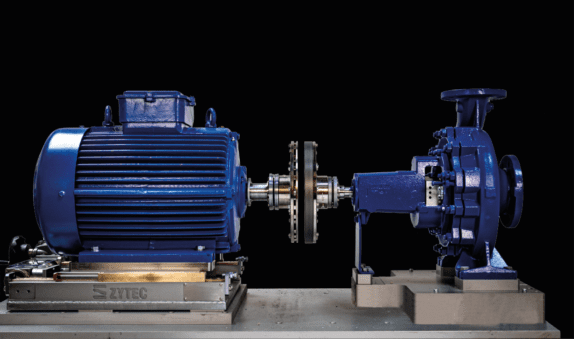

The F-TORQ Non-Contact Drive is designed to make industrial installations more reliable, efficient, and future-proof. Its unique non-contact design resolves a wide range of operational issues, particularly in the areas of maintenance, repairs, and unplanned downtime.

Features

- Standard range for motor power up to 800 kW

- Motor power >800 kW available on request

- Speeds up to 3,600 rpm

- Compatible with Variable Frequency Drives

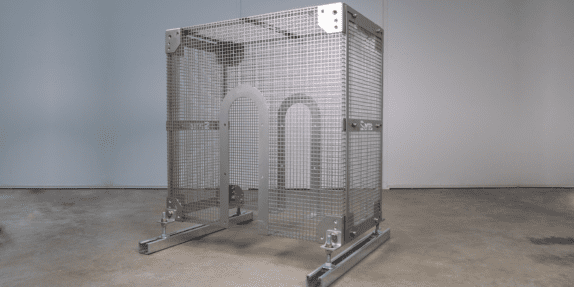

- Suitable for use in EX zones

- Applicable to all types of rotating equipment

What problems does F-TORQ solve?

Less Maintenance

F-TORQ eliminates physical wear on both motor and driven side. This prevents or significantly reduces many common maintenance issues:

- Visual alignment is sufficient, misalignment is irrelevant

- No shaft load on motor or driven side

- Extended maintenance intervals

Result: Low-maintenance operation, reduced costs, and increased system availability.

Less Repairs

Thanks to its damping, non-contact operation, F-TORQ prevents overload, wear, and damage to critical components:

- Dampens shock loads during start/stop, functions as a mechanical soft starter

- Reduces wear on bearings and seals

- Prevents damage from operational misalignment

Result: Less unexpected failures, reduced spare parts stock, less repair planning, and improved safety.

Less Downtime

The greatest cost savings come from reducing both planned and unplanned downtime:

- Up to 80% vibration reduction, lowering the risk of failure

- No realignment needed after installation or revision

- High operational reliability

Result: Maximum uptime, increased production output, and lower Total Cost of Ownership (TCO).