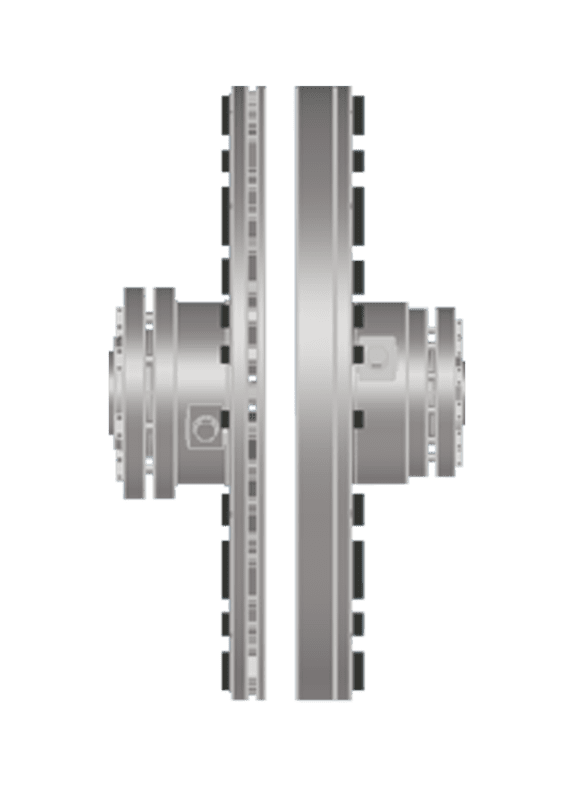

State-of-the-art Non-Contact Drives to

State-of-the-art Non-Contact Drives to

Unleash Magnetic Innovation

Empower Efficiency

Drive Growth

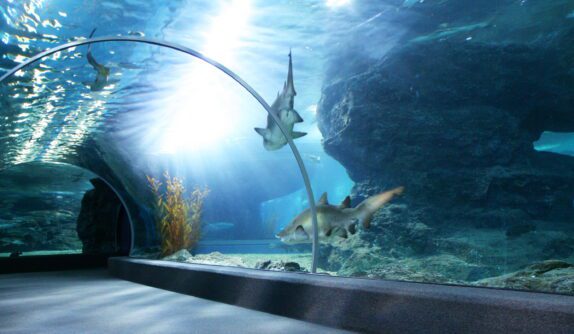

Discover the power of Zytec’s Non-Contact Drives and transform the way you drive your industrial installations.

REDUCE COSTS AND INCREASE RELIABILITY EMBRACE A SUSTAINABLE FUTURE

Improve

Significantly increase the uptime of your industrial installations

Reduce

Decrease your operating costs to the lowest possible level

Eliminate

No more shaft loads that are the root cause of failure

Improve

Significantly increase the uptime of your industrial installations

Reduce

Decrease your operating costs to the lowest possible level

Eliminate

No more shaft loads that are the root cause of failure

Save

Maintenance

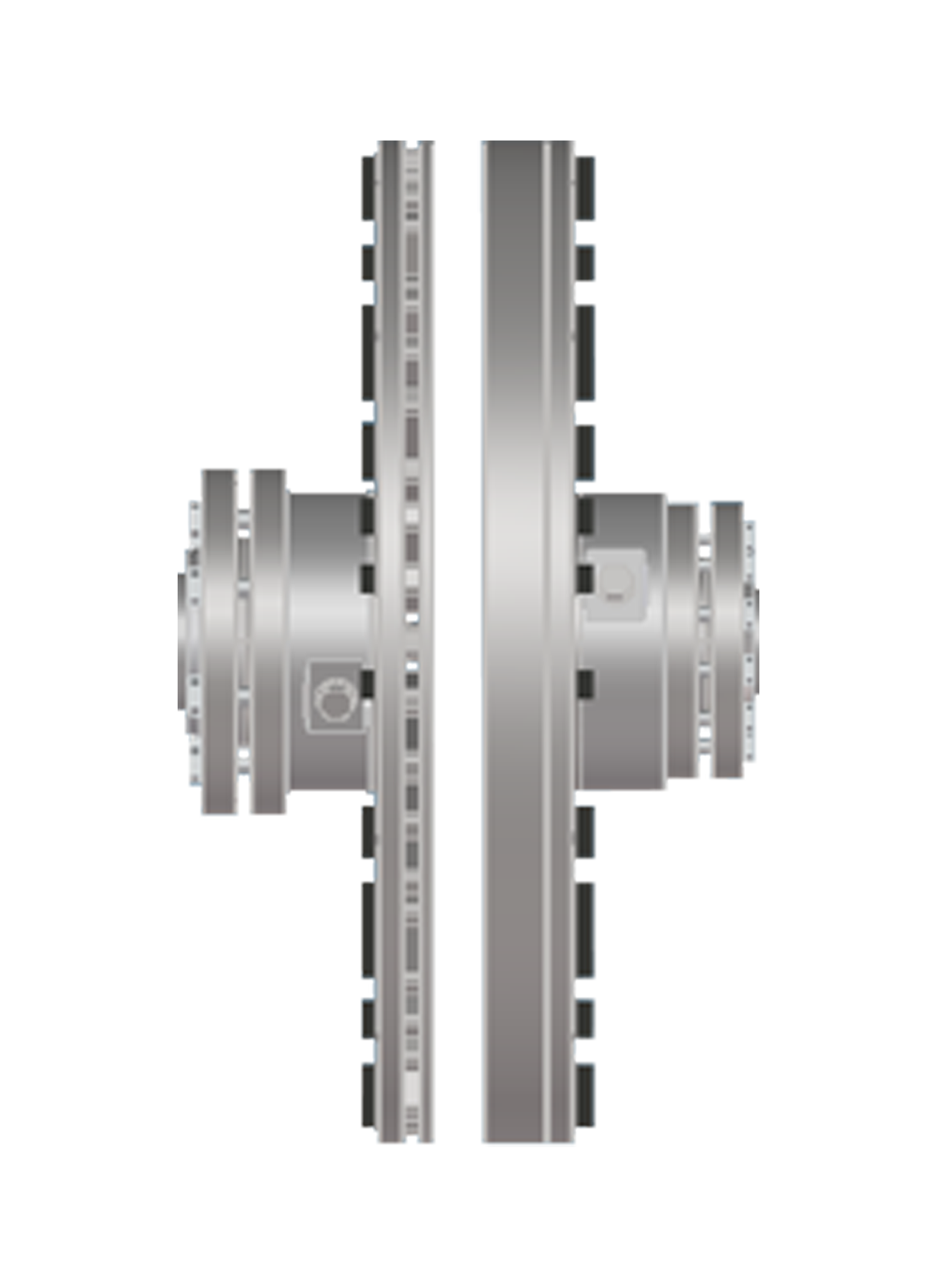

Say goodbye to costly maintenance and frequent repairs. With our Non-Contact Drives, enjoy a maintenance-free solution for uninterrupted operations.

Sustainability

Reduce your carbon footprint and enhance energy efficiency. Zytec’s magnetic coupling technology promotes a greener environment and a sustainable future.

Future-Proof

Stay ahead of the competition with future-proof machinery. Zytec’s Non-Contact Drives are designed to adapt to changing industry demands, ensuring longevity and performance.

Join us in minimizing plant downtime

Our Non-Contact Drive experts are here for you

Realize energy savings of up to 50% in 1 day